Laser Module Overview

Within all signal conditioners produced by Fibos or by Fibos product partners (i.e. Gantner Instruments, Dewesoft), a laser module will exist. The Laser Module (LM) consists of at least three optical components (laser diode, photodiode and circulator), electronics and firmware to control the components. The LM was designed by Fibos and the design can be adapted for new product partners as needed. This page will provide a high-level overview of the LM. For additional details, please reach out to the Fibos team for additional documentation.

How it works

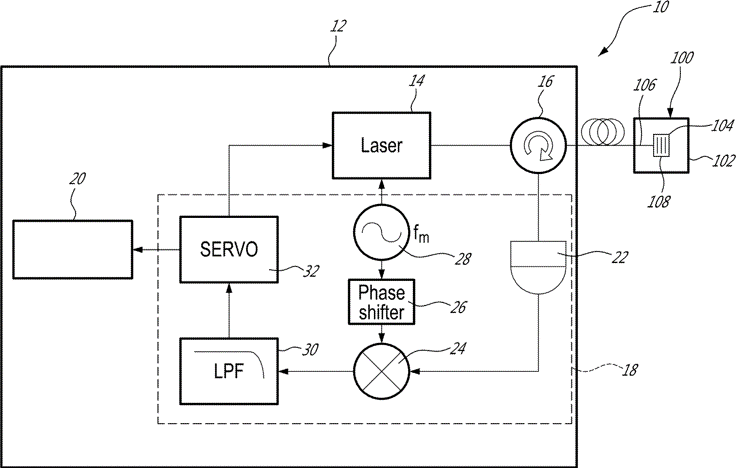

The exact details on how the Laser Module works can be found in the Fibos patent (US20180372566A1). A laser diode (#14) is controlled by the servo (#32) setting the lasers temperature and the lasers current. At a specific temperature and operating current, the laser will emit a known wavelength of light. This light is sent through the optical fiber, into the circulator (#16) and then out to the FBG (#104). If the wavelength of the laser matches the FBG, the reflection will be sent back to the signal conditioner, through the circulator, and directed to the photodiode (#22). The dotted box (#18) indicates all the electronic components.

The received signal is then compared to the lasers output wavelength. If the reflection matches, that means the laser is locked to the sensor (i.e. the wavelengths match). If they do not match, the laser is adjusted via current and temperature to try and achieve a wavelength match.

Once matched, the electronics begin to maintain "lock" to the sensor. This means that the laser is only adjusted if the sensors wavelength begins to differ from the lasers setpoint. The servo provides, via a digital data connection, the wavelength that the laser is set to which correlates to the wavelength that the sensor is currently reflecting. In the digital domain, the wavelength can be correlated to an engineering unit such as temperature, pressure, or vibration via a calibration formula.

Integration

Fibos has developed the Laser Module as a product. This product can then be integrated into data acquisition hardware like any other module that a data acquisition company might interface with. Imagine, for instance, a GPS module. A data acquisition company will source a GPS module from a known supplier and integrate that into their platform. For the GPS company, this means they sell a component rather than having to provide the entire system. For the data acquisition company, this allows them to purchase a specialty component rather than becoming an expert in GPS modules.

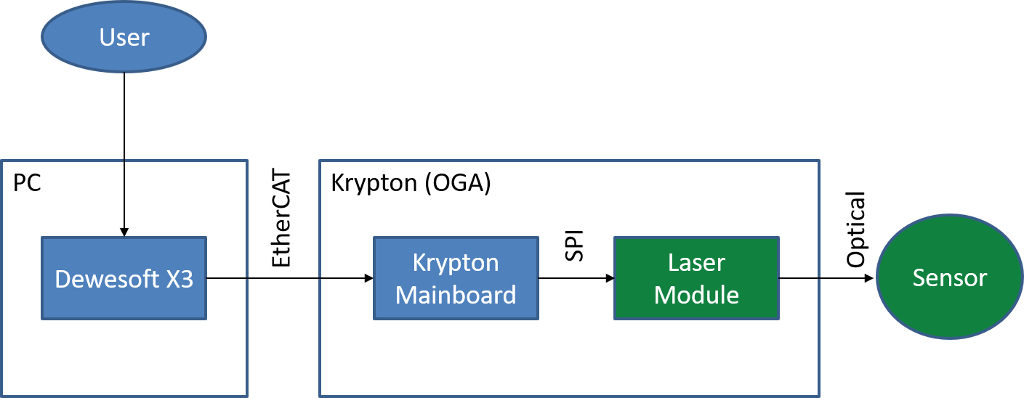

Fibos wants to follow this method with our Laser Module. Fibos wants to remain experts in optical measurements, and we want to enable data acquisition companies to provide optical measurements by adopting our Laser Module. In the graphic below, the items that are green are provided by Fibos. The components in blue would be owned and provided by the data acquisition company. In the image below, we are referencing the Dewesoft solution as an example integration: